ETFE film welding machines

Our ETFE film welding machines offer you

flexible and reliable solutions for the processing of ETFE materials.

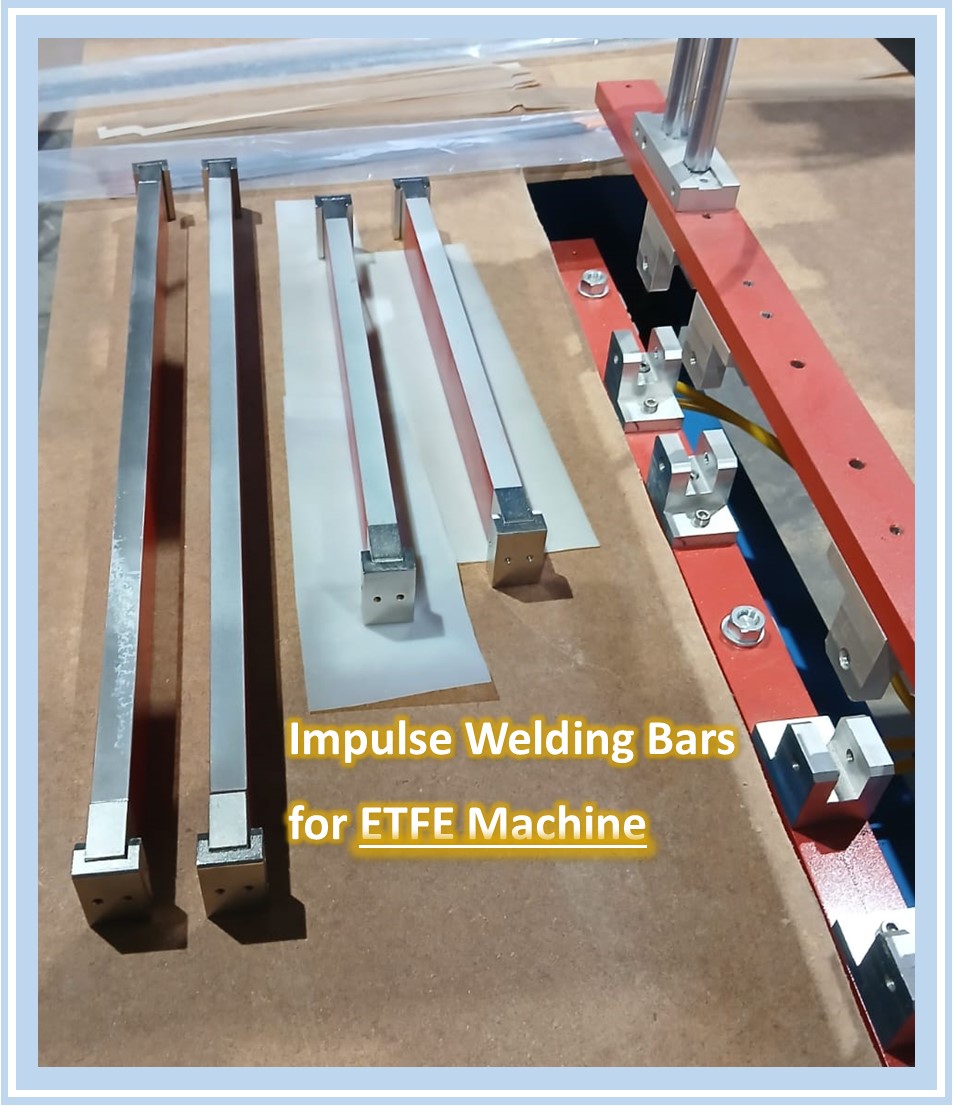

ETFE impulse bar technology

Our pulse bar technology offers flexible and precise solutions for a wide range of welding applications. Whether as a compact, mobile welding machine on wheels or as a stationary unit - this technology ensures maximum efficiency and adaptability.

- Individual sizes and applications: With beam lengths of 300 mm or 500 mm, optionally up to 750 mm, and processing film thicknesses between 100 and 250 micrometers, the machines are ideal for flat and welt seams. The seam width is 11 mm for clean and durable results.

- Customized solutions: In addition to standard applications, we manufacture impulse rails up to a length of 1200 mm as well as special lengths as required.

- Comprehensive accessories: We supply suitable accessories such as impulse tapes, silicone tapes, Teflon tapes, control technology and temperature regulators - everything you need for a smooth welding process.

Rely on our innovative impulse bar technology for your specific welding requirements.

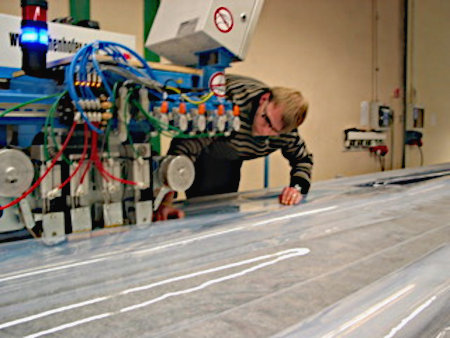

ETFE Continue welding machines

Our continuous ETFE welding machines set standards in efficiency and precision. They are ideal for large-scale welding processes and guarantee the highest quality and reliability thanks to state-of-the-art technology. With a generous production table measuring 12 m x 4 m and a machine guide track of up to 15 m with linear technology, they meet even the most demanding requirements.

- Versatile material processing: The machines process film thicknesses from 100 to 250 micrometers (up to 5 layers) and work with a variable welding speed of 0.4 to 1.3 m/min.

- Precise and high-quality weld seams: They enable perfectly straight seams with a seam width of 11 mm and integrated film cooling technology for clean and long-lasting results.

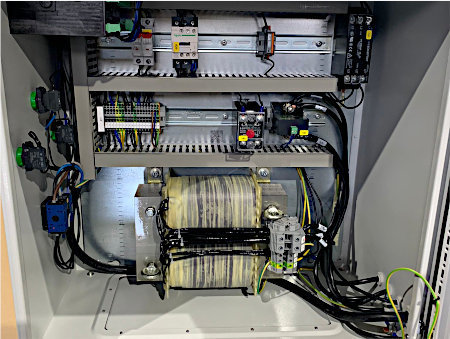

- Maximum process control: Equipped with pressure and temperature sensors as well as finely adjustable process parameters, the machines ensure maximum control and consistent quality in production.

Our continuous ETFE welding machines combine flexibility, reliability and state-of-the-art technology to make your production processes efficient and future-proof.